Moulds for plastic materials

Design and technology

At Omark, we turn your ideas into reality with fully customized moulding solutions. You decide the level of involvement, and our expert team steps in whenever you need support.

From concept to production, our in-house tool room designs and builds cold runner and hot runner moulds that ensure precision, efficiency, and long-lasting quality. We’re here to make your product development faster, smoother, and more reliable.

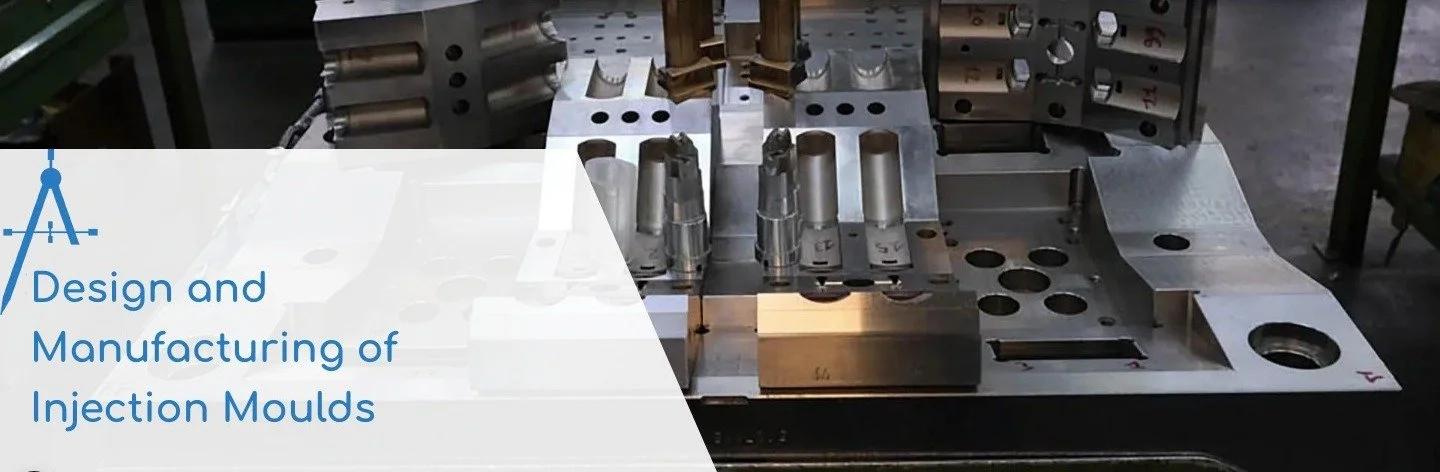

The production of moulds for plastic parts is the result of an accurate design phase. We develop customized solutions, . We can work on the drawing provided by the customer as well as in reverse engineering. Our technical department integrates CAD/CAM software for efficient design to make the subsequent production phases fast and accurate. The competence of our technicians and the constant dialogue with the customer allow us to quickly develop moulds for plastic materials with high standards of efficiency and durability.

We provide precise, high-performance and complete solutions.

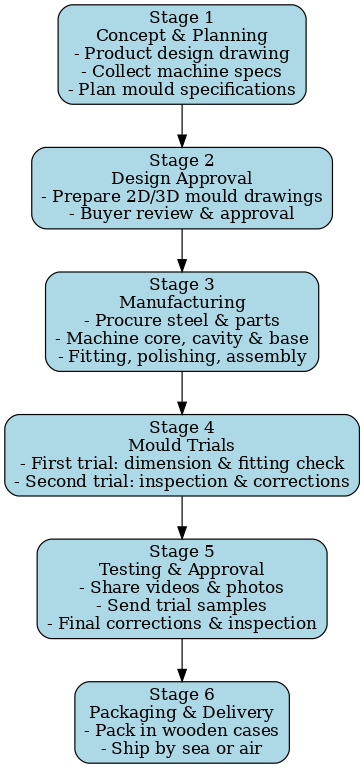

Mould Development

Omark is recognized as one of India’s leading plastic mould manufacturers and exporter offering custom plastic moulding services for diverse industries. With experience, we deliver high-quality moulds designed and manufactured to meet international standards particularly USA.

We specialize in both cold runner and hot runner moulds, with expertise in CAD/CAM/CAE design supported by our advanced technology and skilled engineering team. Our latest achievement includes the development of a high-quality medical Petri Dish mould, designed for precision and reliability.

Our state-of-the-art tool room is fully equipped with high-speed CNC machining centers, CNC milling machines, CNC engraving machines, EDM centers, and wire-cutting equipment, enabling us to provide efficient, accurate, and durable mould solutions.

At Omark, we combine technology, expertise, and innovation to deliver moulds that ensure performance, consistency, and customer satisfaction worldwide.

Make it stand out.

-

Centrifuge tube mould

Precision 15ml and 50 ml Plastic Centrifuge Tube Mould

Mould Material: S136 ,Stainless Mould Steel (ASSAB S136 / AISI 420)

Excellent corrosion resistance, mirror polish, hardness up to 50–52 HRC

Runner: Hot runner

Mould Design: 3D/2D

Design Time: 3–5 days

Mould Life: 500,000 ~ 1,000,000 shots

Plastic Material: PP

-

Cavity High Precision Plastic Medical Petri Dish Mould

Mould Material: S136 ,Stainless Mould Steel (ASSAB S136 / AISI 420)

Excellent corrosion resistance, mirror polish, hardness up to 50–52 HRC

Runner: Hot runner

Mould Design: 3D/2D

Design Time: 3–5 days

Mould Life: 500,000 ~ 1,000,000 shots

Plastic Material: PS/PP

Injection System: Direct gate

Delivery Time: 90 days

Specification: Customized as per customer requirements

-

Plastic Test Tube Mould

Test tube mould made with very good steel - S136 stainless steel with heat treatment,the hardness can be 45~50HRC

The mould life can be 2 million shots.

Mould ejection type: fully automatic ejection.

Cycle time: 10 ~12 seconds

The raw material for test tube is PS.

-

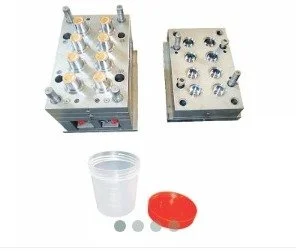

Medical Small Container Mould

Mould Material: S136 ,Stainless Mould Steel (ASSAB S136 / AISI 420)

Excellent corrosion resistance, mirror polish, hardness up to 50–52 HRC

Mould design :3D/2D

Mould life:500, 000~ 1 million shotsPlastic material :HDPE PP injection system direct gate